Ship manoeuvring in shallow and confined water

Knowledge centre

The Knowledge Centre Manoeuvring in Shallow and Confined Water aims to consolidate, extend and disseminate knowledge on the behaviour of ships in shallow and confined water. The Knowledge Centre is a collaboration between Flanders Hydraulics and the Ships and Marine Technology Division at Ghent University. The Knowledge Centre has a dedicated

website, which gives an overview of the various projects that researchers associated with the Centre are involved in and of the experimental facilities that are used for these projects.

Every three years, the Knowledge Centre organizes the MASHCON conferences. Previous editions paid special attention to

The Knowledge Centre has a dedicated

website, which gives an overview of the various projects that researchers associated with the Centre are involved in and of the experimental facilities that are used for these projects.

Every three years, the Knowledge Centre organizes the MASHCON conferences. Previous editions paid special attention to

- Bank effects (Antwerp, 2009)

- Ship - ship interaction (Trondheim, 2011)

- Lock effects (Ghent, 2013)

- Ship - bottom interaction (Hamburg, 2016)

- Manoeuvring in wind, waves and current (Ostend, 2019)

- Ship operations (Glasgow, 2022)

- Clean Power in Shallow Water (Bruges, 2025)

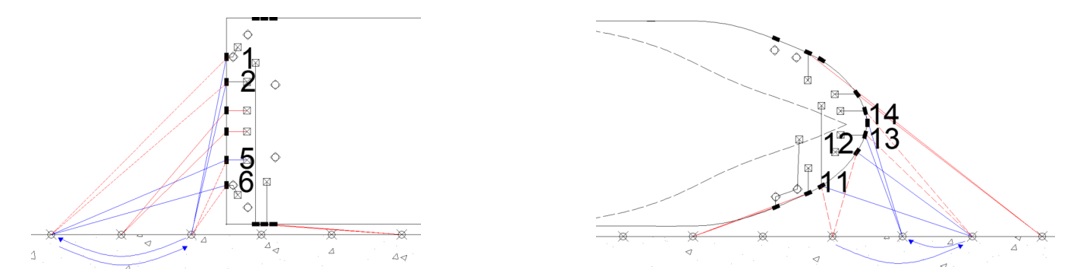

Mooring

With ships getting larger, the safety of (large) moored ships is becoming increasingly important. This concerns both mooring line and fender forces, as well as ship motions. PIANC has established two working groups working on 'safe mooring of large ships at quay walls' ( WG186) and 'update of WG24 - criteria for acceptable movement of ships at berths' ( WG212), both of which the department is involved in. Moored vessels are subjected to external forces of various origins, which are always location dependant, leading to custom studies for each terminal. The external forces include environmental forces (wind, waves, current), as well as passing ship effects. Most services provided by Ghent University up to this day include berth areas which are sheltered from waves (e.g. estuary Scheldt - Antwerp), yet suffer from large wind forces and passing vessel effects. These dynamic mooring analyses (DMA) are performed using the in-house time-domain simulation software

Vlugmoor.

Moored vessels are subjected to external forces of various origins, which are always location dependant, leading to custom studies for each terminal. The external forces include environmental forces (wind, waves, current), as well as passing ship effects. Most services provided by Ghent University up to this day include berth areas which are sheltered from waves (e.g. estuary Scheldt - Antwerp), yet suffer from large wind forces and passing vessel effects. These dynamic mooring analyses (DMA) are performed using the in-house time-domain simulation software

Vlugmoor.

Examples

The department's work focusses on providing expert services, which are often leading to (indirect) publications. These projects also identify gaps in existing knowledge, which are then subject of dedicated research work. Some examples of the work are given below, with references are included in case the work has been published.- For the Port of Antwerp area, several studies have been performed to evaluate the effect of passing ships on moored ships in restricted channels. The Port Authority also provided full scale motion measurements, which have been used for model validation. [Van Zwijnsvoorde, T.; Vantorre, M; Ides, S, 'Container ships moored at the port of Antwerp : Modelling response to passing vessels', PIANC World Congress Panama City, 2018]

- Since ships (gas carriers, RoRo, container ships) are getting larger, passing events become increasingly critical for existing channel dimensions. Numerical predictions reach their limitations in these cases. In order to produce a mathematical model to cope with these conditions, a dedicated model test program has been performed at Flanders Hydraulics Research in spring 2019, called PESCA (Passing Effects in Shallow and Confined Areas). The regression model based on these systematic tests will aid the department in accurately predicting passing ship forces, in today's but also in future cases.

- Incident cases where the moored ship's lines rendered and/or broke have been examined in detail, exposing the reasons for this unwanted event to occur. Rendering winches, as well as breaking lines were modelled in the software, as well as the tugs which were assisting in keeping the vessel moored.

- Literature and informal discussions also reveal that issues with mooring operations and/or inadequate mooring equipment can lead to safety being compromised. Examples here are absence of pretension / slack in lines [Van Zwijnsvoorde, T; Vantorre, M, 'Safe mooring of large container ships at quay walls subject to passing ship effects', Trans RINA, vol 159, part A4, Intl Maritime Eng, Oct-Dec 2017] and use of very elastic lines [Van Zwijnsvoorde, T; Eloot, K; Vantorre, M; Lataire, E, 'A mooring arrangement optimisation study', 11th International Workshop on Ship and Marine Hydrodynamics, Hamburg, Germany, September 22-25, 2019] .

- When dealing with passing ship effects, a standard well-balanced mooring configuration of a container ship at a quay wall can still be optimised, when it comes to mooring operation and ship design phase.

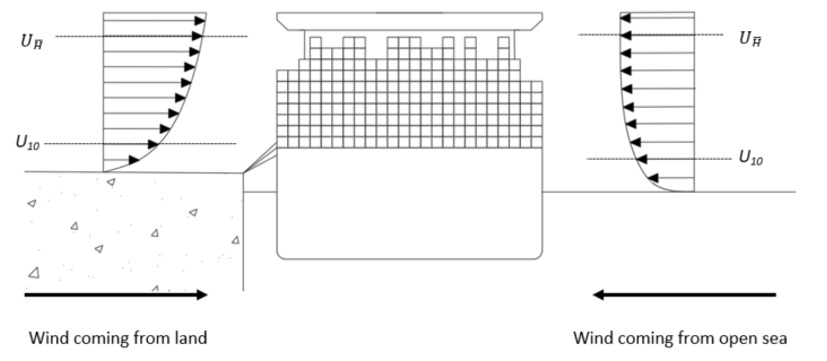

- Air draught and wind area of both cargo as well as passenger ships keep on increasing, which makes them more susceptible to wind effects. Wind forces are usually calculated using simplified formula, concealing the expertise behind them. This has been addressed in [Van Zwijnsvoorde, T; Donatini, L; Van Hoydonck, W, Lataire, E, 'Wind modeling for large container vessels : a critical review of the calculation procedure', Maritime Transport, Italy, Rome, 2019] , revealing potentially large errors with improper use of coefficients, e.g. with differences in wind profile for wind coming from land/sea.

- The effect of passing ships on bunkering ships moored next to large sea-going container ships has been evaluated. Results show that the phase difference in motion between both ships is an important factor contributing to line forces and motions of the bunker vessel.

Nautical bottom

The bottom of a harbour or access channel is mostly considered as solid. In reality this is not always the case. Due to the erosive effect of the current in rivers, particles are transported over a certain distance until they settle again. If those settlements are concentrated at a certain position the formation of a mud layer is possible, depending on the grain size. To avoid excessive formation of mud layers maintenance dredging works are needed so that a minimal under keel clearance can be guaranteed. The question arises how much of the present mud layer has to be dredged. The mud layer consists of a material which characteristics change with the depth. In general the mud characteristics like viscosity or density increase with increasing depth. Therefore the upper part of the mud layer can rather be considered as black water. If the ship's keel touches this upper part it is unlikely that any damage can occur, on the other hand when a ship navigates above a mud layer an undulation of the water mud interface can be observed. This undulation can possibly have adverse effects on the manoeuvring behaviour of the vessel.For these reasons PIANC has introduced the nautical bottom concept (1997, 2014):

The nautical bottom is the level where physical characteristics of the bottom reach a critical limit beyond which contact with a ship's keel causes either damage or unacceptable effects on controllability and manoeuvrability.

Development of a CFD tool and associated experimental validation techniques for fluid mud bottoms disturbed by moving objects

In navigation areas with bottoms covered by a thick fluid mud layer, deep-drafted ships may be allowed to sail at a limited vertical distance above the mud-water separation , and sometimes ships even sail through the mud. This causes a very intense interaction between the water column, the mud layer and the ship. The purpose of this project (in collaboration with KU Leuven and Flanders Hydraulics Research) is to develop a numerical methodology to calculate the interaction between water, mud and a moving object, which will lead to a better understanding of the physical reality in such cases. The project also comprises laboratory tests (at FH) during which either objects are towed, or ship models are navigating in the vicinity of a mud-water interface. This will not only allow a validation of the numerical method, but will also lead to the development of general formulae for estimating forces on flat plates, geometric objects, hydrofoils and ship hulls moving in or close to fluid mud. Such formulations are mostly available for this type of bodies moving in water, but not in mud which has flow properties which are much more complex compared to water. Since classical measuring techniques for water cannot be applied in dense fluid mud layers, new validation techniques are proposed and will be evaluated. The results of the project will lead to a better understanding of the propulsion and manoeuvring of ship in muddy navigation areas, but will also stimulate the development and improvement of measurement techniques and dredging methods in such areas.International cooperations

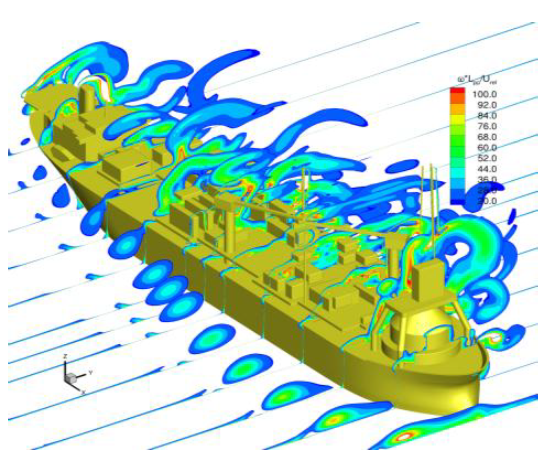

Jores

JoRes is a Joint Research Project aiming at closing the loop between model tests, CFD and the full-scale reality for understanding ship hydrodynamics. The objective is to join the industry research efforts for better understanding of flow field around the ship's hull by gathering full sets of ship performance data, which will also act as an industry recognised benchmark. More than 40 industry and research institutes together with MT Division of Ghent University have joined the project. JoRes will cover the three commonly used spectrums of hydrodynamic analysis i.e: model tests, CFD simulations and full scale measurements. Full scale sea trials, including PIV measurement for propeller flow, of 3 ships will be conducted. The results will be compared to model-scale tests and CFD computation. Through this validation of CFD computations can be carried out which will help to reduce the inherent numerical accuracy and uncertainties in modelling of full-scale flow.

This project will provide a comprehensive set of data for the researchers which will contribute in further developments of efficient design and performance prediction tools and also contribute towards a complete CFD-based performance prediction of ships in the future.

Picture: TT-Sense® (temporarily without its protective cover) developed by VAF instruments.

JoRes will cover the three commonly used spectrums of hydrodynamic analysis i.e: model tests, CFD simulations and full scale measurements. Full scale sea trials, including PIV measurement for propeller flow, of 3 ships will be conducted. The results will be compared to model-scale tests and CFD computation. Through this validation of CFD computations can be carried out which will help to reduce the inherent numerical accuracy and uncertainties in modelling of full-scale flow.

This project will provide a comprehensive set of data for the researchers which will contribute in further developments of efficient design and performance prediction tools and also contribute towards a complete CFD-based performance prediction of ships in the future.

Picture: TT-Sense® (temporarily without its protective cover) developed by VAF instruments.

Windlass

Windlass is an effort to better understand and model the 3-D wind field in ports and waterways trough the development of a practical computer tool to predict wind loads on ships and their response. There is a for such a tool as ships feature increasingly large windage and recent incident have shown that limiting wind conditions are reached earlier than in the past. Current practice to estimate wind loads is based on a wind speed at 10 m height, a vertical velocity profile and a pressure drag coefficient provided by wind tunnel or CFD. Depending on the atmospheric conditions and the landscape, the actual wind field can be quite different resulting in high drift angles, large berthing loads and high mooring line loads for high windage vessels. With the help of Lidar Wind Scanning and Finecasting, insight will be gathered about the wind field around ships and in port environments. In parallel to these wind measurement also relevant vessel response will be measure. These results will be analysed for the modelling of 3-D wind.

The development of such a tool has a large variety of stakeholders: research facilities, port authorities, vessel operators, engineering companies, etc. These companies are brought together in this Joint Industry Project (JIP) which ensures that there is sufficient experience and capabilities available to complete this project.

Current practice to estimate wind loads is based on a wind speed at 10 m height, a vertical velocity profile and a pressure drag coefficient provided by wind tunnel or CFD. Depending on the atmospheric conditions and the landscape, the actual wind field can be quite different resulting in high drift angles, large berthing loads and high mooring line loads for high windage vessels. With the help of Lidar Wind Scanning and Finecasting, insight will be gathered about the wind field around ships and in port environments. In parallel to these wind measurement also relevant vessel response will be measure. These results will be analysed for the modelling of 3-D wind.

The development of such a tool has a large variety of stakeholders: research facilities, port authorities, vessel operators, engineering companies, etc. These companies are brought together in this Joint Industry Project (JIP) which ensures that there is sufficient experience and capabilities available to complete this project.

Ship as a wave buoy

Knowledge of the sea state is one key factor for safe ship operations, the most comprehensive description at least in the statistical sense is given by the directional wave spectrum. Current knowledge of the sea state comes from regular visual observations onboard, sometimes supported by hydrodynamical models based on wave buoys, satellite and weather data. Both data sources have limitations, the visual observation reduces the wave spectrum to a few characteristic numbers like the significant wave height and period and the mean wave direction. Hydrodynamical models can provide directional wave spectra, however, the quality of these spectra might deteriorate for vessels underway, far off the wave buoys which are usually located in coastal areas. In order to establish an independent and autonomous data source, this project aims at estimating the directional wave spectrum from measured ship motions. A new algorithm is developed, basically the wave state is expanded into test functions which are localized in the frequency and angular domain. The well-known response amplitude operators (RAOs) are used to relate the expansion coefficients to measured cross and power spectra of ship motions. Additional conditions are required to generate a solvable set of equations, it assumed that the RAOs vary faster with frequency than the sea state. This set of equations is solved under non-negativity constraints. In a first step the algorithm is tested in numerical simulations based on realistic seaway and RAOs for different existing ships. The numerical tests prove that the algorithm is working albeit currently high frequency parts of sea state are not detected properly. Full scale sea trials are undertaken on three different vessels, the ongoing data evaluation supports the results of the numerical simulations.Simulation studies

Simulator studies for Inland Navigation:

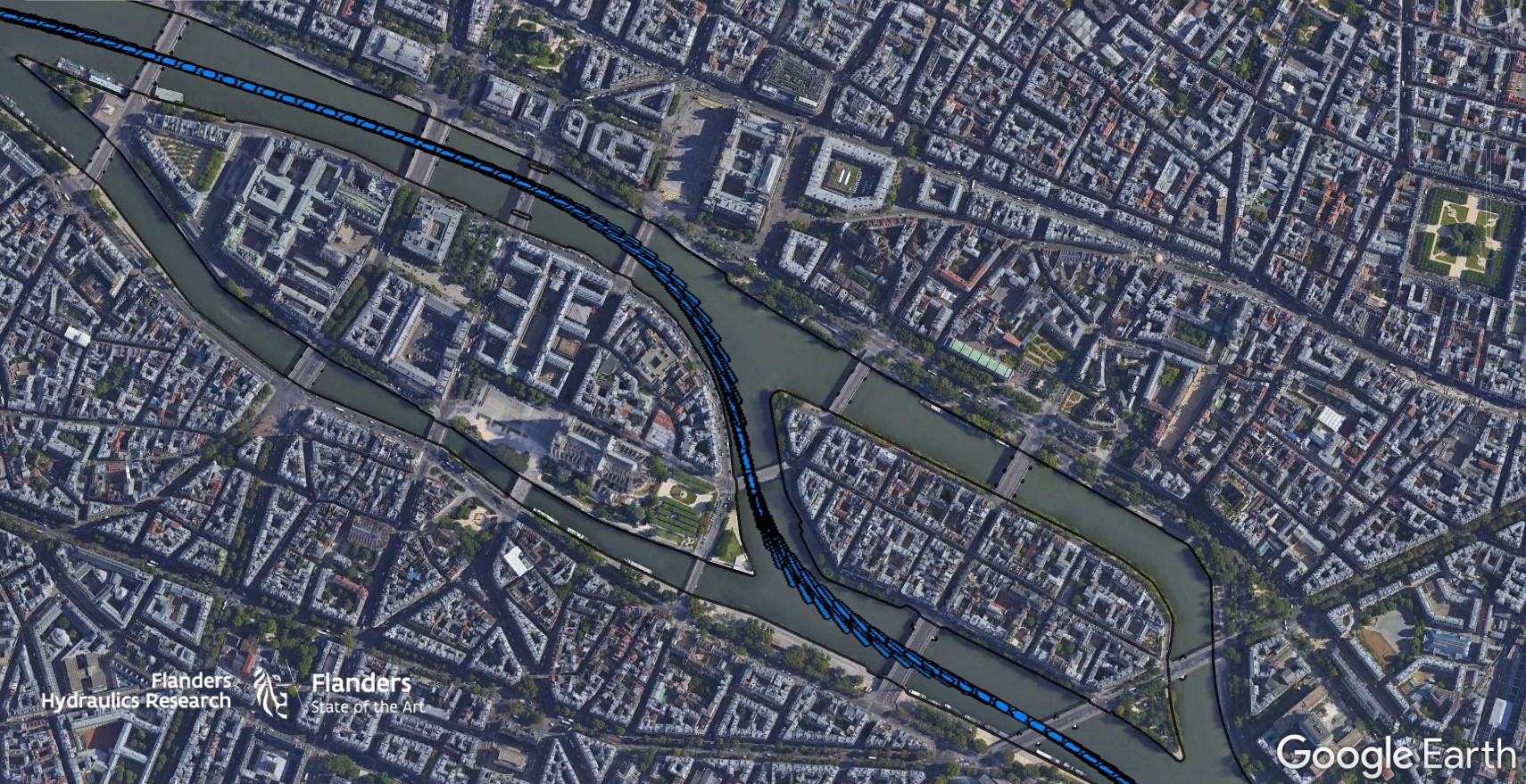

To examine all possible bottlenecks, such as narrow areas, touching the bottom, effect of high current flows, the passage of bridges and quays and encountering other ships, the Ships and Marine Technology Division of UGent execute and analyze real-time simulations to help both national and international companies in defining new traffic regulations, optimized design for infrastructures, optimized dredging... (ex: Grand Gabarit network of Nord-Pas-de-Calais , the Seine River...). These studies show the importance of research and development of manoeuvring models for inland vessels.

To examine all possible bottlenecks, such as narrow areas, touching the bottom, effect of high current flows, the passage of bridges and quays and encountering other ships, the Ships and Marine Technology Division of UGent execute and analyze real-time simulations to help both national and international companies in defining new traffic regulations, optimized design for infrastructures, optimized dredging... (ex: Grand Gabarit network of Nord-Pas-de-Calais , the Seine River...). These studies show the importance of research and development of manoeuvring models for inland vessels.

Fast Time Simulations

UGent execute and analyse fast-time simulations which is a common technique for checking new navigation areas, for assessing channel safety, and for analyzing confined and shallow water effects on ships (ex: Inland vessel sailing around "Île de la Cité" and "Île St Louis" in Paris). The simulation offers a cost-effective and efficient approach for identifying potential risks when designing a fairway. In the fast time simulator, the human input is eliminated and replaced by a control algorithm, here named track-controller. Track-controller is preferred over autopilot in order to avoid confusion with the on-board device with the same name. The track-controller is a control model used in the fast time simulation system, which was initially developed for track-keeping (within restricted deviations) in a confined channel. This algorithm does not only provide new control actions (rudder deflection) at discrete time intervals with the help of a prediction model, which can deal with complex, highly non-linear ship behaviour, but also controls the engine speed thus setting the propeller rate.

The simulation offers a cost-effective and efficient approach for identifying potential risks when designing a fairway. In the fast time simulator, the human input is eliminated and replaced by a control algorithm, here named track-controller. Track-controller is preferred over autopilot in order to avoid confusion with the on-board device with the same name. The track-controller is a control model used in the fast time simulation system, which was initially developed for track-keeping (within restricted deviations) in a confined channel. This algorithm does not only provide new control actions (rudder deflection) at discrete time intervals with the help of a prediction model, which can deal with complex, highly non-linear ship behaviour, but also controls the engine speed thus setting the propeller rate.

Autonomous/unmanned shipping

Track controller

The present track-controller, developed and in use at Flanders Hydraulics and Ghent University, is rather advanced, although the performance of this control system does not always lead to a satisfactory result. In order to optimize the present control system, intelligent and advanced control strategies were taken into account. Apart from the classic PID control theory, fast time simulation track controllers were developed based on adaptive control, fuzzy control, internal model control, and other more advanced or sophisticated tracking control algorithms, such as the model predictive controller (MPC). Video of the model tests in the confined water towing tank at FH:

Complex manoeuvres

The presently available controllers are continuously extending their applicability towards more complex situations, such as ship to ship interaction (e.g. meeting, overtaking, passing of moored vessels, ship-tug interaction); and complex harbour manoeuvres requiring thruster and/or tug assistance (e.g. berthing, lock entrance, turning manoeuvres). In order to do so, state-of-the-art control techniques are studied and then tested by free running model tests, also in the towing tank for manoeuvres in shallow water (Ostend). Since 2021 free running model tests can be executed with multiple ships of different sizes (between 4 and 8 m long). Updated controllers are integrated in the ship manoeuvring simulators and are tested for their effectiveness in one or more practical cases in Belgium or worldwide, which focusses on typical local conditions.Foiling

The use of hydrofoils has been around for a long time but has recently experienced some kind of renaissance. This can for a large part be attributed to the introduction of hydrofoils in the America's Cup in 2013 but what are hydrofoils and what do they do? Hydrofoils are, similar to the wings of an airplane, structures which, when placed under a certain angle of attack in a fluid flow, generate lift. This lift can then partly or completely replace the buoyant force of a vessel, which is means as much as "the vessel starts flying". Some of the most notable advantages are the ensuing drag reduction and the decoupling of the vessel's movement from waves as the hull now flies above the water surface.

The use of hydrofoils has been around for a long time but has recently experienced some kind of renaissance. This can for a large part be attributed to the introduction of hydrofoils in the America's Cup in 2013 but what are hydrofoils and what do they do? Hydrofoils are, similar to the wings of an airplane, structures which, when placed under a certain angle of attack in a fluid flow, generate lift. This lift can then partly or completely replace the buoyant force of a vessel, which is means as much as "the vessel starts flying". Some of the most notable advantages are the ensuing drag reduction and the decoupling of the vessel's movement from waves as the hull now flies above the water surface.

Assessing the stability of a ship with and without hydrofoils are two very distinct practices. That is why we put out an effort to develop a framework to perform a dynamic stability analysis to be able to quantify dynamic characteristics and to be able to quickly compare the influence of design parameters on the stability behaviour. To support this framework we develop the easy to use the open source software Typhoon based on the vortex lattice method.

Assessing the stability of a ship with and without hydrofoils are two very distinct practices. That is why we put out an effort to develop a framework to perform a dynamic stability analysis to be able to quantify dynamic characteristics and to be able to quickly compare the influence of design parameters on the stability behaviour. To support this framework we develop the easy to use the open source software Typhoon based on the vortex lattice method.

SeaBubbles manoeuvring tests 2D video (1080p):

SeaBubbles manoeuvring tests 360 video (4K):

Mega Yachts

Design of Structural Glass Domes on Superyachts

Glass in superyachts

The use of glass in the design of superyachts is an innovative method of increasing the comfort and spatial experience on board the vessel while also providing striking aesthetics. Currently, there exists a trend in the superyacht industry in increasing the amount of glass used in the construction of the vessel. Increasing the size of windows give passengers a greater sense of the outside world. Larger glazed areas also allow more natural light into the yacht. Besides the use of glass as conventional windows, glass in the overhead areas of the superstructure have also been of interest to yacht designers. These so called 'glass domes', cover an expansive area of the superstructure and provide a near transparent ceiling with spectacular views of the natural surroundings.

Increasing glass dome transparancy

Major limitations are imposed on the dimensions of uninterrupted glazed areas due to the presence of the structural components of the superyacht. Due to the brittle nature of glass, shipbuilders still make use of conventional structural materials for load-bearing applications. The use of structural glass presents a solution to significantly increase the transparency of a glass dome on a superyacht, thereby replacing the use of opaque structural materials. However, there is currently no clear way of using glass as a structural, load-bearing component in ships. The aim of the project is to determine whether glass can be used as a structural load-bearing element in a glass dome in order to maximise the transparency of the dome. Particular attention is given to force transfer and stress distribution in the glass, the structural connections between the glass and the superstructure, as well as the durability in the marine environment.

This project is supported by both the Ships and Marine Technology Division and the Structural Glass Research Group at Ghent University. The consortium of the project also includes the engineering company Multi Engineering and the superyacht builder Oceanco.

The aim of the project is to determine whether glass can be used as a structural load-bearing element in a glass dome in order to maximise the transparency of the dome. Particular attention is given to force transfer and stress distribution in the glass, the structural connections between the glass and the superstructure, as well as the durability in the marine environment.

This project is supported by both the Ships and Marine Technology Division and the Structural Glass Research Group at Ghent University. The consortium of the project also includes the engineering company Multi Engineering and the superyacht builder Oceanco.

Aquaculture

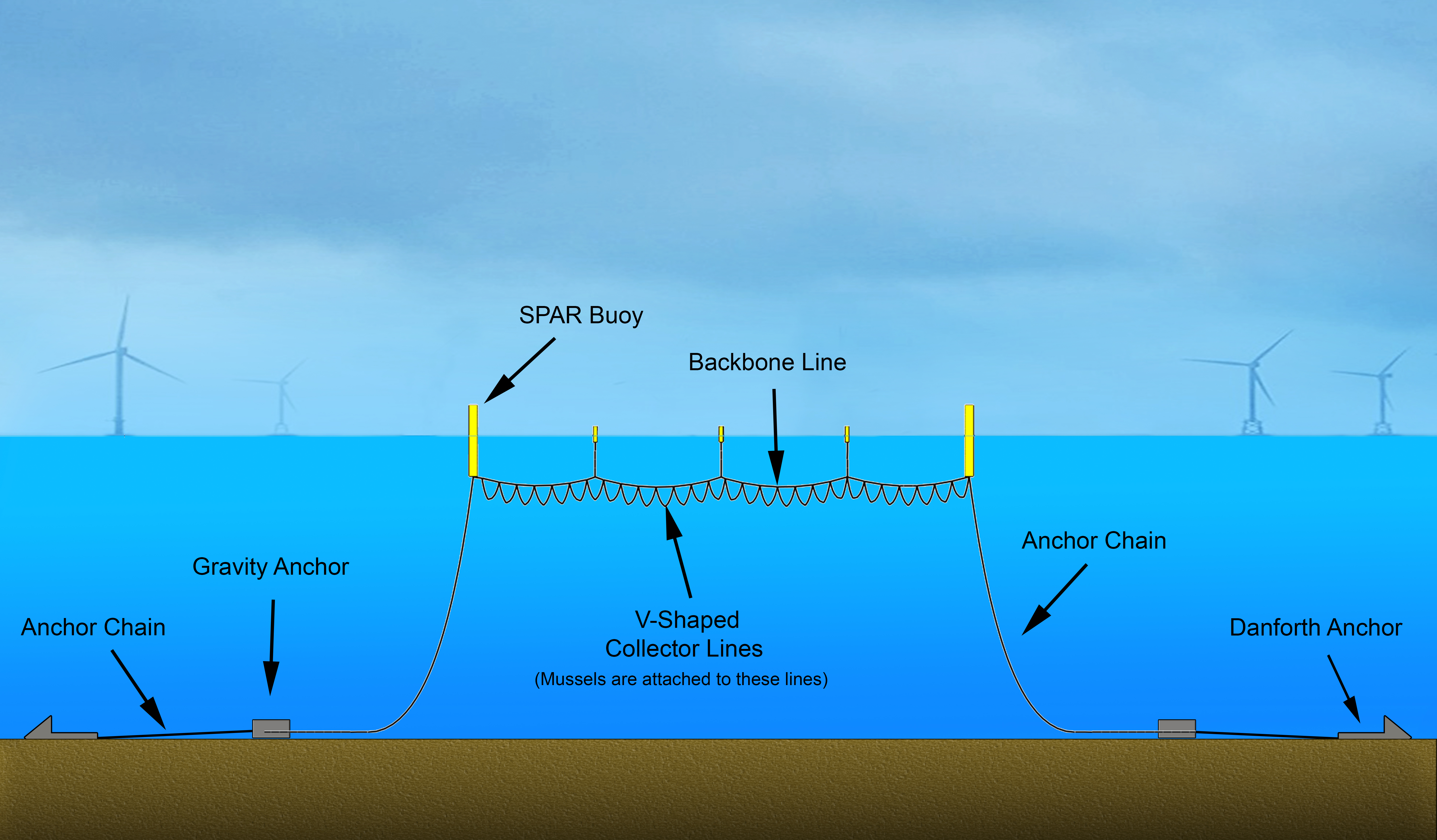

Edulis: Offshore mussel culture in wind farm

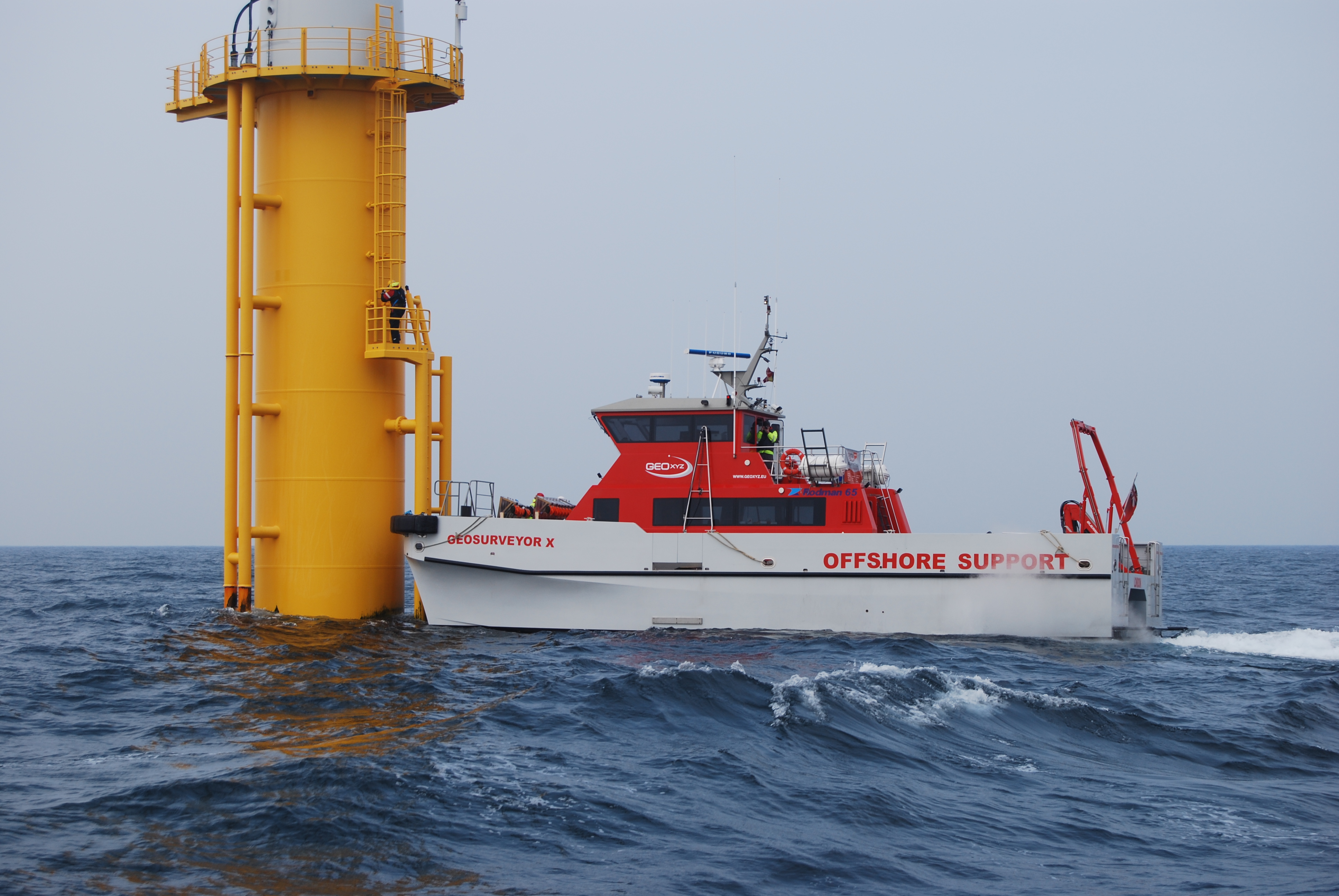

The

Marine Spatial Plan (MSP) allows for commercial aquaculture activities in the Belgian part of the North Sea. Following this MSP, the

Edulis project was initiated in 2017 to study the feasibility of growing mussel off the coast within the wind turbine parks of Belwind and C-power. Five private partners are involved in this project: Belwind, Brevisco, C-Power, Colruyt Group and DEME Group. Ghent University collaborated with the Institute for Agriculture, Fisheries and Food Research (ILVO) to conduct this research project. OD Natural Environment is also involved as a third research partner. The project is largely financed by private funding and facilitated by Flemish and European Funding.

The

Marine Spatial Plan (MSP) allows for commercial aquaculture activities in the Belgian part of the North Sea. Following this MSP, the

Edulis project was initiated in 2017 to study the feasibility of growing mussel off the coast within the wind turbine parks of Belwind and C-power. Five private partners are involved in this project: Belwind, Brevisco, C-Power, Colruyt Group and DEME Group. Ghent University collaborated with the Institute for Agriculture, Fisheries and Food Research (ILVO) to conduct this research project. OD Natural Environment is also involved as a third research partner. The project is largely financed by private funding and facilitated by Flemish and European Funding.

Two full scale test setups were installed: Bio line and Force line. The Bio line was put into the water in May 2017 to study the growth of the mussels. In November 2017, the Force line was installed to measure the forces and positions of the system. In 2019, as planned, both lines were decommissioned.

Two full scale test setups were installed: Bio line and Force line. The Bio line was put into the water in May 2017 to study the growth of the mussels. In November 2017, the Force line was installed to measure the forces and positions of the system. In 2019, as planned, both lines were decommissioned.

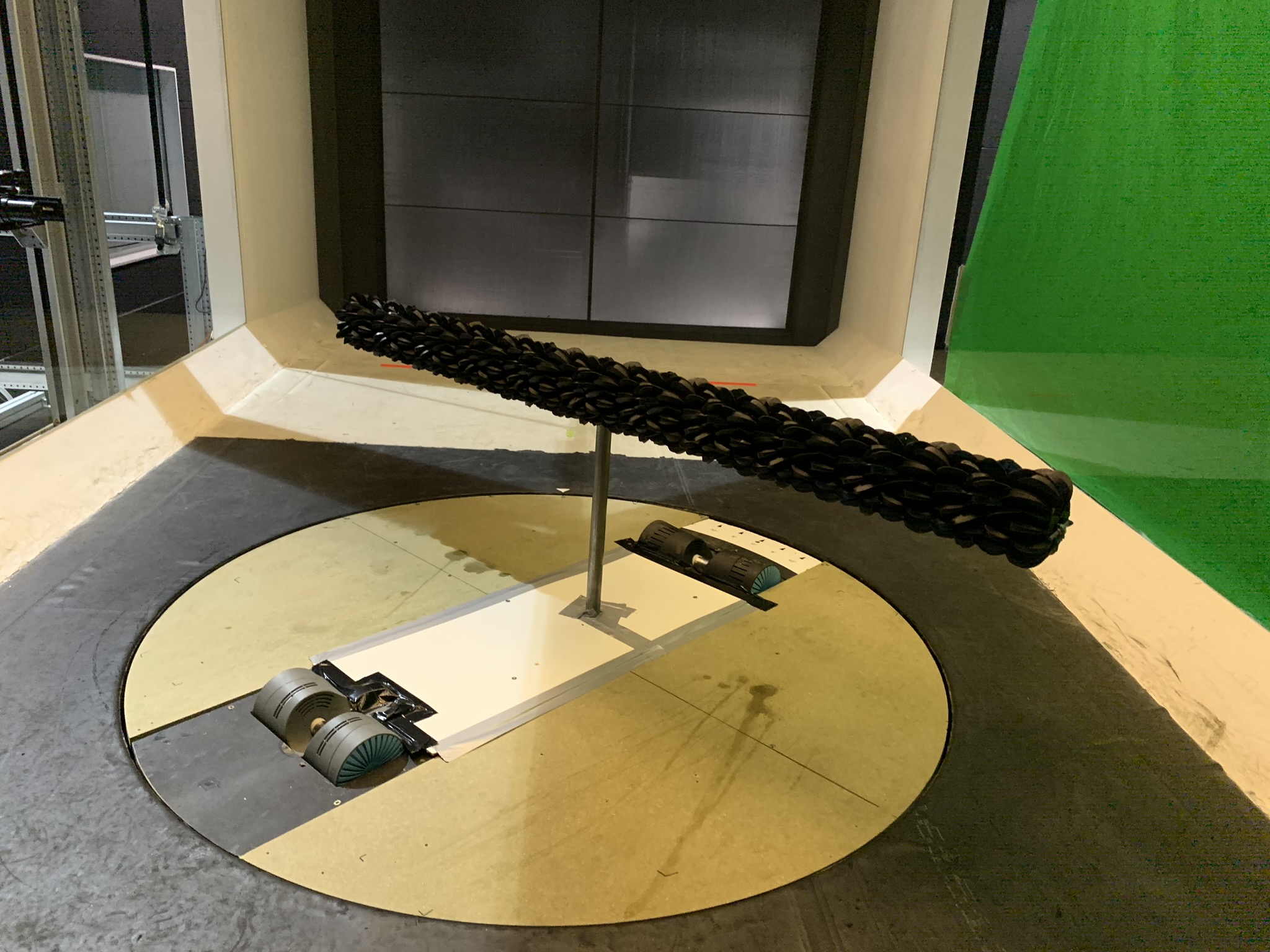

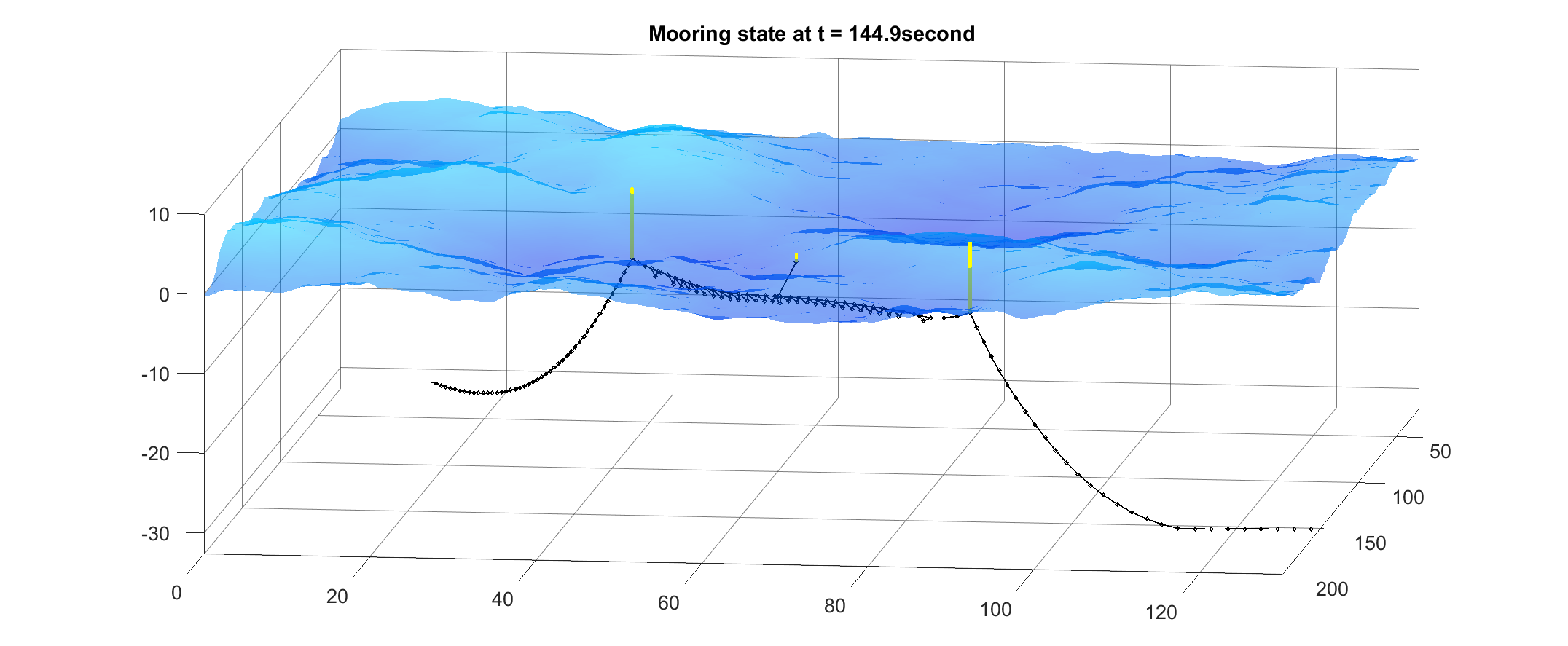

The Ships and Marine Technology Division has worked in the design process of the proposed array of mussel line system, namely park layout, for the deployment location of the Belgium part of the North Sea. The design process includes development of a numerical tool (Moordyn-UGent), validation with full scale test setup (Force Line), experiments carried out in a wind tunnel and extreme case simulations of the park layout.

The Ships and Marine Technology Division has worked in the design process of the proposed array of mussel line system, namely park layout, for the deployment location of the Belgium part of the North Sea. The design process includes development of a numerical tool (Moordyn-UGent), validation with full scale test setup (Force Line), experiments carried out in a wind tunnel and extreme case simulations of the park layout.

Wier en Wind: Large scale seaweed culture in the North Sea

The

interreg (Vlaanderen-Nederland)

Wier en Wind project aims to provide a commercial benchmark for large scale seaweed cultivation in the offshore environment. Additionally, the seaweed farm will be located within a wind turbine park in order to contribute to the multi-use of the North Sea reducing the unused space in between wind turbines. Automation using machinery for the process of seeding and harvesting is going to be implemented in this project. This is done to achieve a lower production cost per kg of seaweed. The on-going project involves several private partners as well as public institutes: GEOxyz, Seaweed Harvest Holland, Murre Technologies, Noordzeeboerderij, Ghent University (UGent), HZ University of Applied Science and AtSeaNova as project coordinator.

The role of Ships and Marine Technology Division is to calculate the mooring system used for the offshore seaweed farm layout designed by AtSeaNova. In order to perform the numerical simulation, MoorDyn-UGent will be developed and modified to cope with seaweed layout design under environmental load of waves and currents at the deployment location. Engineering requirement of the mooring system is the expected outcome of these numerical calculations.

The

interreg (Vlaanderen-Nederland)

Wier en Wind project aims to provide a commercial benchmark for large scale seaweed cultivation in the offshore environment. Additionally, the seaweed farm will be located within a wind turbine park in order to contribute to the multi-use of the North Sea reducing the unused space in between wind turbines. Automation using machinery for the process of seeding and harvesting is going to be implemented in this project. This is done to achieve a lower production cost per kg of seaweed. The on-going project involves several private partners as well as public institutes: GEOxyz, Seaweed Harvest Holland, Murre Technologies, Noordzeeboerderij, Ghent University (UGent), HZ University of Applied Science and AtSeaNova as project coordinator.

The role of Ships and Marine Technology Division is to calculate the mooring system used for the offshore seaweed farm layout designed by AtSeaNova. In order to perform the numerical simulation, MoorDyn-UGent will be developed and modified to cope with seaweed layout design under environmental load of waves and currents at the deployment location. Engineering requirement of the mooring system is the expected outcome of these numerical calculations.

H2020 UNITED PROJECT

The multi-use policies of the North Sea, encouraged by the European Union, have brought up new commercial opportunities for the offshore and aquaculture sectors. The UNITED project appears as a joint effort between industry partners and Ghent University to enhance aquaculture in the vicinity of offshore wind parks. The project is also an international project comprising partners from Belgium, The Nederland, Germany, Denmark and Greece. There are five pilots representing each country:- FINO3 site – Germany

- North Sea Innovation Lab site – The Netherlands

- BelWind site – Belgium

- Middelgrunden Wind site – Denmark

- Patroklos site - Greece

Of all pilots, the Ships and Marine Technology Division of Ghent University (MTD UGent) is involved in Pilot 1, 2 and 3. In Pilot 1, an offshore research platform, namely FINO3 in the German part of the North Sea is used to conduct offshore wind and aquaculture demonstration activities within the UNITED project. One of the activities involved aquaculture of Blue Mussel or/and Macroalgae. The design and construction of this project will be coordinated by FuE FH Kiel. Based on the provided design by FuE FH Kiel, MTD UGent will perform numerical simulations with the expected outcomes of forces and positions in time series. These outcomes will provide an understanding of the maximum expected forces based on provided loading conditions as well as the displacement of system in space.

In the Netherlands, one of the objectives of Pilot 2 is to provide safe operation within the integration of multiple aquaculture activities, namely seaweed deployed at offshore wind farms. The research tasks of the MTD UGent is to calculate the forces on the floating structure and the positions of the system to ensure the integrity of the system and a minimum impact on the wind infrastructures. In Belgium, the project will help to restore the Belgium wild oyster reefs. Wild oyster reefs have seen their population drastically reduced due to overfishing and diseases over the 20th century and the scour protection used in offshore wind farms can become the solution for their decreasing population. The possibility of restoring and cultivating wild oysters in the scour protection used at the foundations of offshore wind turbines will be studied. This is a unique challenge where not only the implementation of oyster aquaculture in a harsh offshore environment will be designed, but the integrity of the scour protection must be ensured. The research tasks of MTD UGent is to provide numerical calculations of the longline systems used to grow the oysters. The output of this calculations will be the load suffered by the structure, as well as, the relative position of the system to avoid damaging the existing offshore wind structures.

Of all pilots, the Ships and Marine Technology Division of Ghent University (MTD UGent) is involved in Pilot 1, 2 and 3. In Pilot 1, an offshore research platform, namely FINO3 in the German part of the North Sea is used to conduct offshore wind and aquaculture demonstration activities within the UNITED project. One of the activities involved aquaculture of Blue Mussel or/and Macroalgae. The design and construction of this project will be coordinated by FuE FH Kiel. Based on the provided design by FuE FH Kiel, MTD UGent will perform numerical simulations with the expected outcomes of forces and positions in time series. These outcomes will provide an understanding of the maximum expected forces based on provided loading conditions as well as the displacement of system in space.

In the Netherlands, one of the objectives of Pilot 2 is to provide safe operation within the integration of multiple aquaculture activities, namely seaweed deployed at offshore wind farms. The research tasks of the MTD UGent is to calculate the forces on the floating structure and the positions of the system to ensure the integrity of the system and a minimum impact on the wind infrastructures. In Belgium, the project will help to restore the Belgium wild oyster reefs. Wild oyster reefs have seen their population drastically reduced due to overfishing and diseases over the 20th century and the scour protection used in offshore wind farms can become the solution for their decreasing population. The possibility of restoring and cultivating wild oysters in the scour protection used at the foundations of offshore wind turbines will be studied. This is a unique challenge where not only the implementation of oyster aquaculture in a harsh offshore environment will be designed, but the integrity of the scour protection must be ensured. The research tasks of MTD UGent is to provide numerical calculations of the longline systems used to grow the oysters. The output of this calculations will be the load suffered by the structure, as well as, the relative position of the system to avoid damaging the existing offshore wind structures.

Other floating devices

MPVAQUA: High-wave offshore solar panels.

The Belgium part of the North Sea is occupied by several largewind turbine parks. The large distance between two single wind turbines (up to 1km) has created large areas of unused space. In the past years, the Belgian Government has been encouraging the multi-use of the North Sea to obtain a more efficient use of the available space. Installing arrays of floating photovoltaic (PV) panels within offshore wind turbine parks will not only utilize the otherwise unused space, but also to have additional electricity generation. The idea is to use the available space in the most efficient way, along with aquaculture and existing offshore wind farms. The

project is under the framework of Flemish Blue Cluster and the consortium consists of Tractebel, Jan De Nul Group, DEME, Soltech and Ghent University (UGent) with the support of VLAIO. The Ships and Marine Technology Division of UGent takes the role in the calculation of the mooring system used for the floaters. Modifications to the MoorDyn-UGent software will be done to cope with floating large object subjected to environmental induced load of waves and currents.

The

project is under the framework of Flemish Blue Cluster and the consortium consists of Tractebel, Jan De Nul Group, DEME, Soltech and Ghent University (UGent) with the support of VLAIO. The Ships and Marine Technology Division of UGent takes the role in the calculation of the mooring system used for the floaters. Modifications to the MoorDyn-UGent software will be done to cope with floating large object subjected to environmental induced load of waves and currents.

Phairywind

The objectives of the PhairywinD project are threefold: research, training and mobility, but it is the link between these objectives that makes this project unique. The 9 research topics on the most important aspects of offshore wind will deliver scientifically based answers to the challenges met by the Belgian offshore wind industry. All researchers will be deployed in one Belgian university or research institute, where they perform their research under the supervision of their promoters, thus becoming specialists in their own field.